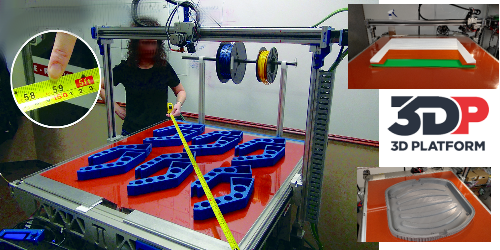

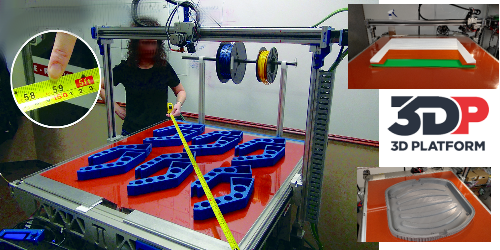

PCS Additive Manufacturing is headquartered in Timonium, Maryland. We provide products and services for the medical, mechanical, architectural, civil engineering and other areas of design and product development and manufacturing.

By providing superior products and support, PCS Additive Manufacturing has become the "Best in Class" provider in the Mid-Atlantic region. PCS, Is there to help you bring your products and services to market quicker and for less.

The original PCS, Inc. was founded in 1986 after seeing that the Computer Aided Design and Computer Aided Manufacturing (CAD/CAM) industries were lacking the technology that the rest of the industry was enjoying. It has since emerged as a leader in the computer-integrated manufacturing service by developing state-of-the-art software, hardware, and training designed specifically to suit CAD/CAM industries with enhanced technological tools and training. The modern PCS, Inc. is now providing these same technology upgrades across a wide variety of industry from dental 3D models to RTV molding of the latest widget invention.

Plastic

Metal

Finishing Options

3D-Printed Ship Turbine Ready For Open SeasBREAKTHROUGH: 3-D printed turbine spins at 13,000 RPM and 2,200°F!

Posted by Vocativ on Thursday, June 29, 2017

German

RepRap X350

The engineer’s desktop 3D printer is here: The X350 is a fully assembled desktop 3D printer loaded with all the features necessary for professional use.

The X350 German RepRap remains true to its pioneering roots in providing cutting-edge technology 3D printers, developed and designed to meet the needs of industrial users and demanding consumers. There is no 3D printer available with a more optimized print space compared to its size. The rectangular build platform allows better utilization of the print area. Most 3D print systems don’t have a square foot print. A highlight of this device is the integrated web interface that allows operation via WiFi or LAN through a standard web browser.

Product description:

Print Technology: Fused deposition modeling (FDM), aka Fused Filament Fabrication (FFF)

Build Volume: 350 L x 200 W x 210 H mm [13.8 L x 7.9 W x 8.3 H in]

Accuracy: +/- 0.005″

Filament: 1.75 mm filament of any available thermoplastic (PLA, ABS, PET, and more)

Nozzle Diameter: 0.4mm (available 0.25, 0.35, 0.4, 0.6, 0.8 and 1mm)

Printing Bed: Heated bed (max 120 C / 248 F)

German RepRap X400

The German RepRap X400 has been extensively tweaked. calibrated, enhanced, and improved upon by the professionals at 3DChimera.

The World’s First Industrial Quality, Open Source 3D Printer never fails to impress all types of development teams with its high precision, speed and large printing volume.

The X400 3D printer can be found in companies of all sizes and all sectors such as the car industry, textile and chemical industry, electronics and consumer goods manufacturers, tool construction, casting houses, the building industry, architects and designers, 3D printing providers as well as research, development and teaching institutions. Highly reliability, combined with a comprehensive service contract, mean s the X400 3D printer turns CAD designs into models for such applications as: customer presentations, testing the fitting accuracy of components, mold preparation and prototyping.

Product Description:

Print Technology: Fused deposition modeling (FDM), aka Fused Filament Fabrication (FFF)

Build Volume: 40 L x 40 W x 35 H cm [15.7 L x 15.7 W x 13.7 H in]

Accuracy: +/- 0.005″

Filament: 1.75 mm filament of any available thermoplastic (PLA, ABS, PET, and more)

Nozzle Diameter: 0.4mm (available 0.25, 0.35, 0.4, 0.6, 0.8 and 1mm)

Starting at $52,499.00

The new X1000 3D Printer is being developed for printing large size objects or multi-object prints with industrial quality. The X1000 comes with 1000 x 800 x 600 mm [39 x 31 x 23] printing space and many features our industrial users have requested.

Product Description

Features:

Intelligent filament management with time-out

Integrated clean-up function for the extruder nozzle

Touch display

Large printing space

Network compatible

Technical Data:

Size: 1350 x 1700 x 1300 mm

Printing space: 1000 x 800 x 600 mm

Weight:400 kg

Large, closed build envelope with safety-door switch:

The enclosed build envelope avoids poor quality prints due to air flow. An automatic door locking mechanism keeps the hatch closed during the printing process for improved safety.

Direct Drive DD3 Extruder with Full Metal Hotend:

New extruder technology, no adjustment necessary, variable contact pressure. High-heat Hotend (up to 290° C / 554° F) for industrial filaments. Hotends can be exchanged

quickly and easily.

Print fast and precise:

A minimum layer high from 0.1 mm allow precise prints. Larger nozzles will allow for faster printing of large objects.

Easy to use printing software with pre-defined printing profiles and many features.

Filament Management:

Two sensor filament controls prevents useless prints due to filament run out.

File transfer:

Network compatible via Wifi or Ethernet.

Important safety features for industrial use:

Closed switchboard, emergency shut-down, twofold CO2 fire extinguishing systems (optional).

German

RepRap X350

The engineer’s desktop 3D printer is here: The X350 is a fully assembled desktop 3D printer loaded with all the features necessary for professional use.

The X350 German RepRap remains true to its pioneering roots in providing cutting-edge technology 3D printers, developed and designed to meet the needs of industrial users and demanding consumers. There is no 3D printer available with a more optimized print space compared to its size. The rectangular build platform allows better utilization of the print area. Most 3D print systems don’t have a square foot print. A highlight of this device is the integrated web interface that allows operation via WiFi or LAN through a standard web browser.

Product description:

Print Technology: Fused deposition modeling (FDM), aka Fused Filament Fabrication (FFF)

Build Volume: 350 L x 200 W x 210 H mm [13.8 L x 7.9 W x 8.3 H in]

Accuracy: +/- 0.005″

Filament: 1.75 mm filament of any available thermoplastic (PLA, ABS, PET, and more)

Nozzle Diameter: 0.4mm (available 0.25, 0.35, 0.4, 0.6, 0.8 and 1mm)

Printing Bed: Heated bed (max 120 C / 248 F)

German RepRap X400

The German RepRap X400 has been extensively tweaked. calibrated, enhanced, and improved upon by the professionals at 3DChimera.

The World’s First Industrial Quality, Open Source 3D Printer never fails to impress all types of development teams with its high precision, speed and large printing volume.

The X400 3D printer can be found in companies of all sizes and all sectors such as the car industry, textile and chemical industry, electronics and consumer goods manufacturers, tool construction, casting houses, the building industry, architects and designers, 3D printing providers as well as research, development and teaching institutions. Highly reliability, combined with a comprehensive service contract, mean s the X400 3D printer turns CAD designs into models for such applications as: customer presentations, testing the fitting accuracy of components, mold preparation and prototyping.

Product Description:

Print Technology: Fused deposition modeling (FDM), aka Fused Filament Fabrication (FFF)

Build Volume: 40 L x 40 W x 35 H cm [15.7 L x 15.7 W x 13.7 H in]

Accuracy: +/- 0.005″

Filament: 1.75 mm filament of any available thermoplastic (PLA, ABS, PET, and more)

Nozzle Diameter: 0.4mm (available 0.25, 0.35, 0.4, 0.6, 0.8 and 1mm)

Starting at $52,499.00

The new X1000 3D Printer is being developed for printing large size objects or multi-object prints with industrial quality. The X1000 comes with 1000 x 800 x 600 mm [39 x 31 x 23] printing space and many features our industrial users have requested.

Product Description

Features:

Intelligent filament management with time-out

Integrated clean-up function for the extruder nozzle

Touch display

Large printing space

Network compatible

Technical Data:

Size: 1350 x 1700 x 1300 mm

Printing space: 1000 x 800 x 600 mm

Weight:400 kg

Large, closed build envelope with safety-door switch:

The enclosed build envelope avoids poor quality prints due to air flow. An automatic door locking mechanism keeps the hatch closed during the printing process for improved safety.

Direct Drive DD3 Extruder with Full Metal Hotend:

New extruder technology, no adjustment necessary, variable contact pressure. High-heat Hotend (up to 290° C / 554° F) for industrial filaments. Hotends can be exchanged

quickly and easily.

Print fast and precise:

A minimum layer high from 0.1 mm allow precise prints. Larger nozzles will allow for faster printing of large objects.

Easy to use printing software with pre-defined printing profiles and many features.

Filament Management:

Two sensor filament controls prevents useless prints due to filament run out.

File transfer:

Network compatible via Wifi or Ethernet.

Important safety features for industrial use:

Closed switchboard, emergency shut-down, twofold CO2 fire extinguishing systems (optional).

x400 Pro v4

Regular price $14,999.00

Updated from the best-selling x400 v3 (blue housing), the x400 v4 comes packed with a number of amazing new features: auto bed-leveling, filament out sensor, touch screen control, industrial computing power, and network connectivity.

Preconfigured with a 1.75 mm hotend from the world-renowned experts @ e3D, the x400 is compatible with all e3D nozzles sizes for quick printing or to focus on finer details. With an all-new machined aluminum extruder, the x400 can print virtually any material right out of the box – PLA, ABS, HIP, PVA, PET…even TPU!

The x400 has been optimized for professional users, who push the limits of 3D printing in design and engineering roles across all industries – consumer products, automotive, marine, industrial, and fabrication. With its transparent housings, the x400 is also an excellent 3D printer for educational environments – K-12 (Middle School / High School), Community Colleges and Universities.

From Robotics Teams and Engineering Classrooms to the Production Floor, the x400 is built to last with all the quality that we have come to expect from German Engineering! Configured with the technical user in mind, the x400 features machined aluminum components, low-play gears, high accuracy trapezoidal spindles, and hardened guide rods. There are no 3D printed parts to worry about warping or breaking on the x400 – every single component critical to accuracy is custom-machined in Germany for the absolute highest precision possible.

Bundled with everything you need – Full-Enclosure, Dual Extruders, Heated Build Plate, 2x Spool Holders, 2x Build Plate Adhesives, Simplify3D, a SD Card, and even a roll of material to get you printing trouble free right out of the box! Speaking of Simplify 3D and the x400 – it’s a perfect match! Simplify3D is a powerful 3D printing software that provides complete control over your print settings, making it easier to consistently produce high-quality 3D prints. Start up quickly with pre-configured settings optimized for the x400, review a simulation of your build sequence in the Preview Mode, and begin your 3D print with confidence.

The electronic components are Arduino-based, and are compatible with all Open Source RepRap firmware, enabling in-house or community-based changes with ease.

| Extruders | DD3 Dual, 1.75 mm |

| Extruder Temp (Max) | 290C / 554F |

| Resolution (max) | 100 microns (0.1mm) |

| Heated Bed | Ceramic |

| Heated Bed Temp (Max) | 110C / 230F |

| Build Volume | 390 x 400 x 310 mm 15.4" x 15.7" x 12.2" |

| Nozzles | 0.25 mm, 0.4 mm (std), 0.6 mm, 0.8 mm |

| Speed (max) | 200mm/s |

| Speed | Up to 200 mm/s |

| Resolution | Up to 100 microns (0.1 mm) |

| Materials | Open Material Configuration including PETG, PLA, TPE, DuPont Zytel (Nylon), DuPont Hytrel (Flexible) |

| Software | Simplify3D (1 license included, 2 installs) |

| Files Transfer | LCD Touch Display, Network via Ethernet or USB |

| Voltage | 110V |

| Weight | 110lbs |

$41,999.00

The x500 has a completely new precision measuring technology with its new DD4 Extruders. The technology allows variable contact pressure for the filament and has a pre-set setting for all GRR filaments. The movement of the filament is tracked by sensors and synchronized live with filament feeding. This guarantees a precise and constant material flow, eliminating errors caused by twisted filament spools or inconsistent material flow.

| Extruders | DD4 Dual, 1.75 mm |

| Extruder Temp (Max) | 400C / 752F (up to 450C / 842F w/ High Temp Config) |

| Resolution (max) | 20 microns (0.02mm) |

| Heated Bed | Ceramic Plate (removeable) |

| Heated Bed Temp (max) | 120C / 248F (up to 150C / 302F w/ High Temp Config) |

| Heated Chamber | Actively Heated |

| Heated Chamber Temp (max) | 80C / 176F (up to 110C / 230F w/ High Temp Config) |

| Build Volume | 500 x 400 x 475 mm / 19.7" x 15.7" x 18.7" |

| Nozzles | 0.25 mm, 0.4 mm (std), 0.6 mm, 0.8 mm *Available in Brass or Hardened Steel |

| Speed (max) | 150 mm/s |

| Materials | Open-Material Configuration, including PEKK-Carbon, Ultem, Nylon, PA-Carbon, Metal-Fill, ABS, PLA, PVA, PET, HiPS, TPU, Carbon20, Dupont Zytel (Nylon), DuPont Hytrel (Flexible) |

| Voltage | 230V European Standard, Schuko (110V Transformer available) |

| Power | 4400W max |

| Weight | 375 lbs |

German

RepRap X350

The engineer’s desktop 3D printer is here: The X350 is a fully assembled desktop 3D printer loaded with all the features necessary for professional use.

The X350 German RepRap remains true to its pioneering roots in providing cutting-edge technology 3D printers, developed and designed to meet the needs of industrial users and demanding consumers. There is no 3D printer available with a more optimized print space compared to its size. The rectangular build platform allows better utilization of the print area. Most 3D print systems don’t have a square foot print. A highlight of this device is the integrated web interface that allows operation via WiFi or LAN through a standard web browser.

Product description:

Print Technology: Fused deposition modeling (FDM), aka Fused Filament Fabrication (FFF)

Build Volume: 350 L x 200 W x 210 H mm [13.8 L x 7.9 W x 8.3 H in]

Accuracy: +/- 0.005″

Filament: 1.75 mm filament of any available thermoplastic (PLA, ABS, PET, and more)

Nozzle Diameter: 0.4mm (available 0.25, 0.35, 0.4, 0.6, 0.8 and 1mm)

Printing Bed: Heated bed (max 120 C / 248 F)

German RepRap X400

The German RepRap X400 has been extensively tweaked. calibrated, enhanced, and improved upon by the professionals at 3DChimera.

The World’s First Industrial Quality, Open Source 3D Printer never fails to impress all types of development teams with its high precision, speed and large printing volume.

The X400 3D printer can be found in companies of all sizes and all sectors such as the car industry, textile and chemical industry, electronics and consumer goods manufacturers, tool construction, casting houses, the building industry, architects and designers, 3D printing providers as well as research, development and teaching institutions. Highly reliability, combined with a comprehensive service contract, mean s the X400 3D printer turns CAD designs into models for such applications as: customer presentations, testing the fitting accuracy of components, mold preparation and prototyping.

Product Description:

Print Technology: Fused deposition modeling (FDM), aka Fused Filament Fabrication (FFF)

Build Volume: 40 L x 40 W x 35 H cm [15.7 L x 15.7 W x 13.7 H in]

Accuracy: +/- 0.005″

Filament: 1.75 mm filament of any available thermoplastic (PLA, ABS, PET, and more)

Nozzle Diameter: 0.4mm (available 0.25, 0.35, 0.4, 0.6, 0.8 and 1mm)

Starting at $52,499.00

The new X1000 3D Printer is being developed for printing large size objects or multi-object prints with industrial quality. The X1000 comes with 1000 x 800 x 600 mm [39 x 31 x 23] printing space and many features our industrial users have requested.

Product Description

Features:

Intelligent filament management with time-out

Integrated clean-up function for the extruder nozzle

Touch display

Large printing space

Network compatible

Technical Data:

Size: 1350 x 1700 x 1300 mm

Printing space: 1000 x 800 x 600 mm

Weight:400 kg

Large, closed build envelope with safety-door switch:

The enclosed build envelope avoids poor quality prints due to air flow. An automatic door locking mechanism keeps the hatch closed during the printing process for improved safety.

Direct Drive DD3 Extruder with Full Metal Hotend:

New extruder technology, no adjustment necessary, variable contact pressure. High-heat Hotend (up to 290° C / 554° F) for industrial filaments. Hotends can be exchanged

quickly and easily.

Print fast and precise:

A minimum layer high from 0.1 mm allow precise prints. Larger nozzles will allow for faster printing of large objects.

Easy to use printing software with pre-defined printing profiles and many features.

Filament Management:

Two sensor filament controls prevents useless prints due to filament run out.

File transfer:

Network compatible via Wifi or Ethernet.

Important safety features for industrial use:

Closed switchboard, emergency shut-down, twofold CO2 fire extinguishing systems (optional).

$41,999.00

The x500 has a completely new precision measuring technology with its new DD4 Extruders. The technology allows variable contact pressure for the filament and has a pre-set setting for all GRR filaments. The movement of the filament is tracked by sensors and synchronized live with filament feeding. This guarantees a precise and constant material flow, eliminating errors caused by twisted filament spools or inconsistent material flow.

| Extruders | DD4 Dual, 1.75 mm |

| Extruder Temp (Max) | 400C / 752F (up to 450C / 842F w/ High Temp Config) |

| Resolution (max) | 20 microns (0.02mm) |

| Heated Bed | Ceramic Plate (removeable) |

| Heated Bed Temp (max) | 120C / 248F (up to 150C / 302F w/ High Temp Config) |

| Heated Chamber | Actively Heated |

| Heated Chamber Temp (max) | 80C / 176F (up to 110C / 230F w/ High Temp Config) |

| Build Volume | 500 x 400 x 475 mm / 19.7" x 15.7" x 18.7" |

| Nozzles | 0.25 mm, 0.4 mm (std), 0.6 mm, 0.8 mm *Available in Brass or Hardened Steel |

| Speed (max) | 150 mm/s |

| Materials | Open-Material Configuration, including PEKK-Carbon, Ultem, Nylon, PA-Carbon, Metal-Fill, ABS, PLA, PVA, PET, HiPS, TPU, Carbon20, Dupont Zytel (Nylon), DuPont Hytrel (Flexible) |

| Voltage | 230V European Standard, Schuko (110V Transformer available) |

| Power | 4400W max |

| Weight | 375 lbs |

x400 Pro v4

Regular price $14,999.00

Updated from the best-selling x400 v3 (blue housing), the x400 v4 comes packed with a number of amazing new features: auto bed-leveling, filament out sensor, touch screen control, industrial computing power, and network connectivity.

Preconfigured with a 1.75 mm hotend from the world-renowned experts @ e3D, the x400 is compatible with all e3D nozzles sizes for quick printing or to focus on finer details. With an all-new machined aluminum extruder, the x400 can print virtually any material right out of the box – PLA, ABS, HIP, PVA, PET…even TPU!

The x400 has been optimized for professional users, who push the limits of 3D printing in design and engineering roles across all industries – consumer products, automotive, marine, industrial, and fabrication. With its transparent housings, the x400 is also an excellent 3D printer for educational environments – K-12 (Middle School / High School), Community Colleges and Universities.

From Robotics Teams and Engineering Classrooms to the Production Floor, the x400 is built to last with all the quality that we have come to expect from German Engineering! Configured with the technical user in mind, the x400 features machined aluminum components, low-play gears, high accuracy trapezoidal spindles, and hardened guide rods. There are no 3D printed parts to worry about warping or breaking on the x400 – every single component critical to accuracy is custom-machined in Germany for the absolute highest precision possible.

Bundled with everything you need – Full-Enclosure, Dual Extruders, Heated Build Plate, 2x Spool Holders, 2x Build Plate Adhesives, Simplify3D, a SD Card, and even a roll of material to get you printing trouble free right out of the box! Speaking of Simplify 3D and the x400 – it’s a perfect match! Simplify3D is a powerful 3D printing software that provides complete control over your print settings, making it easier to consistently produce high-quality 3D prints. Start up quickly with pre-configured settings optimized for the x400, review a simulation of your build sequence in the Preview Mode, and begin your 3D print with confidence.

The electronic components are Arduino-based, and are compatible with all Open Source RepRap firmware, enabling in-house or community-based changes with ease.

| Extruders | DD3 Dual, 1.75 mm |

| Extruder Temp (Max) | 290C / 554F |

| Resolution (max) | 100 microns (0.1mm) |

| Heated Bed | Ceramic |

| Heated Bed Temp (Max) | 110C / 230F |

| Build Volume | 390 x 400 x 310 mm 15.4" x 15.7" x 12.2" |

| Nozzles | 0.25 mm, 0.4 mm (std), 0.6 mm, 0.8 mm |

| Speed (max) | 200mm/s |

| Speed | Up to 200 mm/s |

| Resolution | Up to 100 microns (0.1 mm) |

| Materials | Open Material Configuration including PETG, PLA, TPE, DuPont Zytel (Nylon), DuPont Hytrel (Flexible) |

| Software | Simplify3D (1 license included, 2 installs) |

| Files Transfer | LCD Touch Display, Network via Ethernet or USB |

| Voltage | 110V |

| Weight | 110lbs |

PCS Additive Manufacturing is headquartered in Timonium, Maryland. We provide products and services for the medical, mechanical, architectural, civil engineering and other areas of design and product development and manufacturing.

By providing superior products and support, PCS Additive Manufacturing has become the "Best in Class" provider in the Mid-Atlantic region. PCS, Is there to help you bring your products and services to market quicker and for less.

The original PCS, Inc. was founded in 1986 after seeing that the Computer Aided Design and Computer Aided Manufacturing (CAD/CAM) industries were lacking the technology that the rest of the industry was enjoying. It has since emerged as a leader in the computer-integrated manufacturing service by developing state-of-the-art software, hardware, and training designed specifically to suit CAD/CAM industries with enhanced technological tools and training. The modern PCS, Inc. is now providing these same technology upgrades across a wide variety of industry from dental 3D models to RTV molding of the latest widget invention.

Plastic

Metal

Finishing Options

3D-Printed Ship Turbine Ready For Open SeasBREAKTHROUGH: 3-D printed turbine spins at 13,000 RPM and 2,200°F!

Posted by Vocativ on Thursday, June 29, 2017

$59,999.00

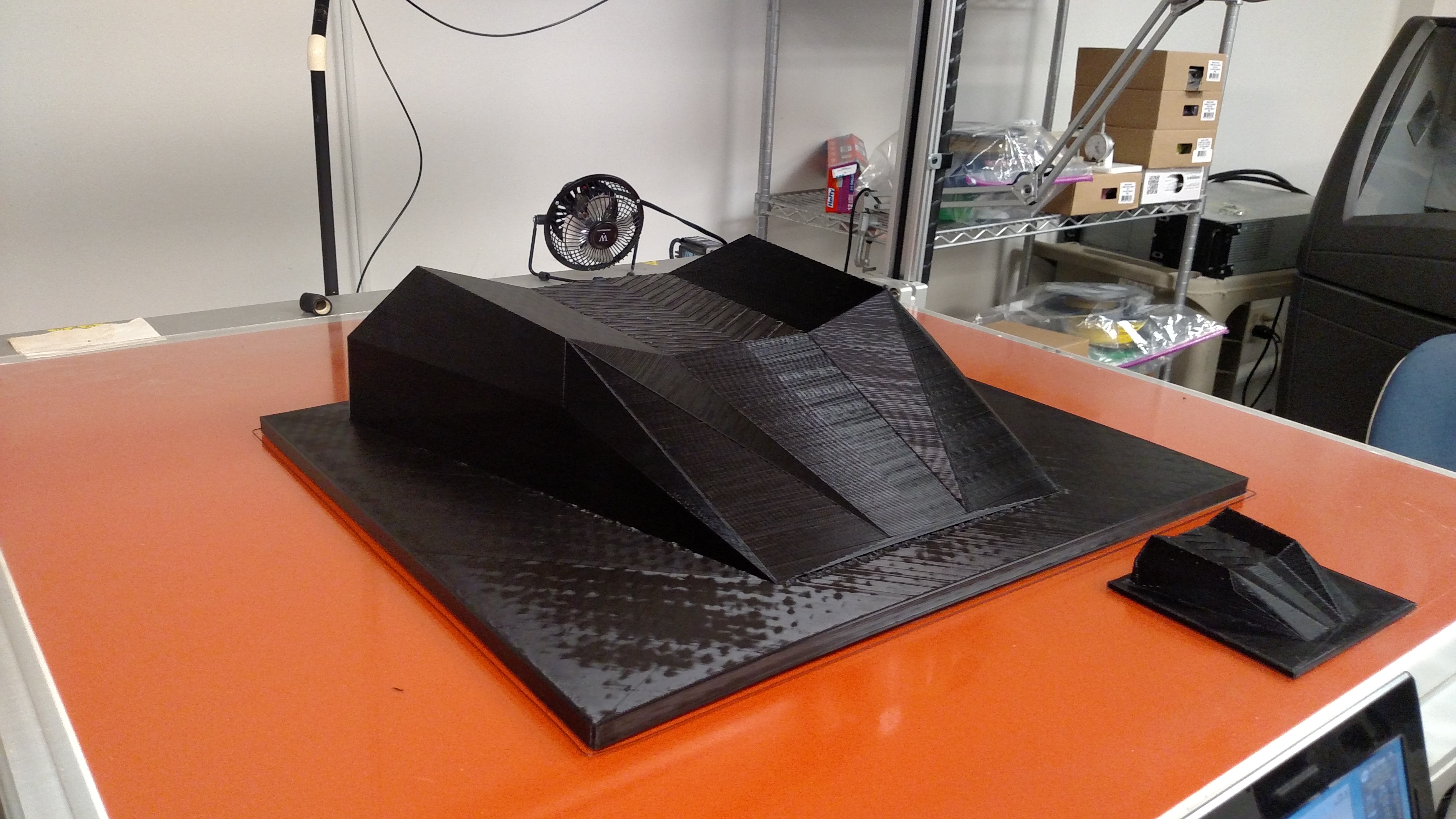

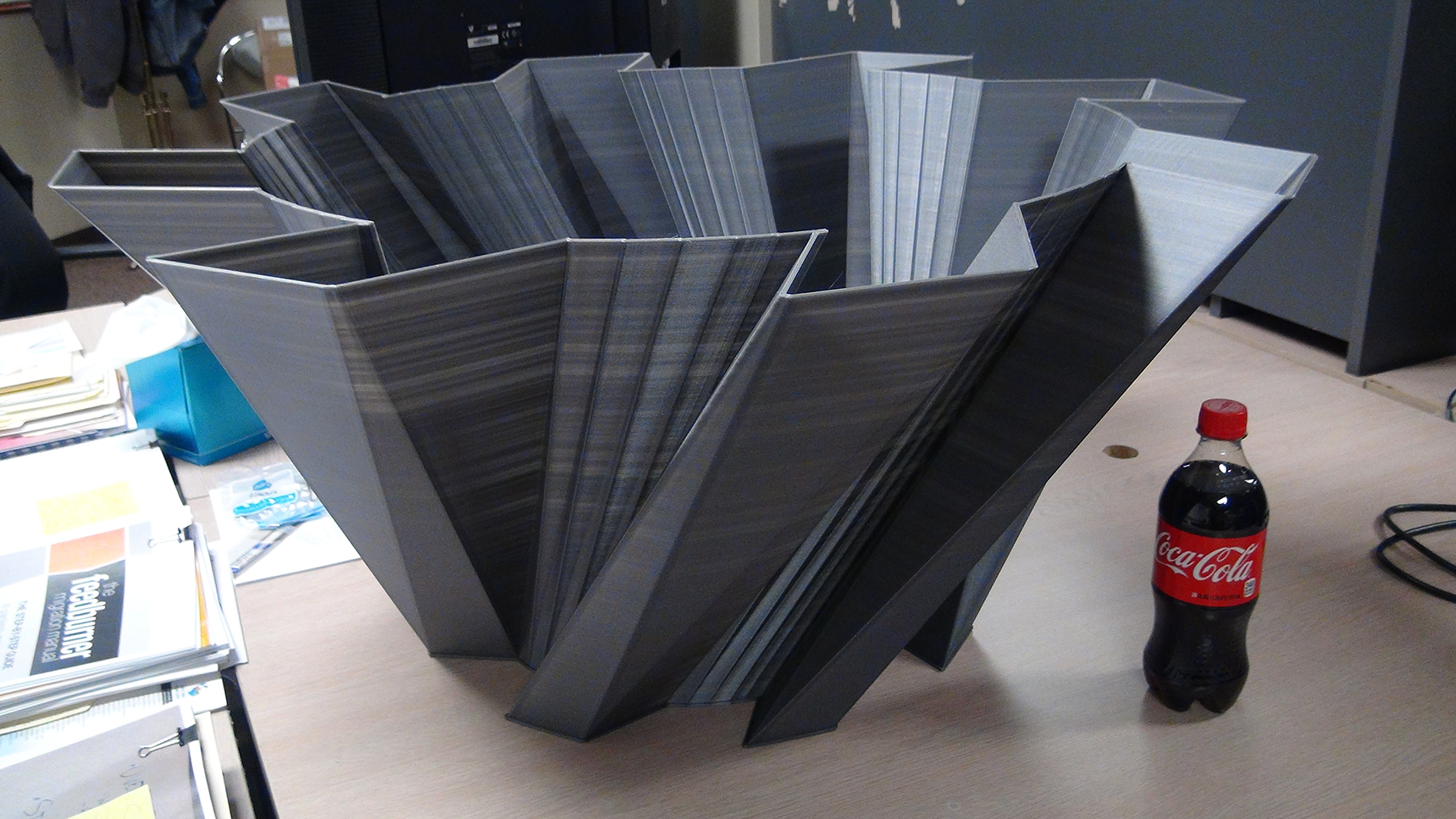

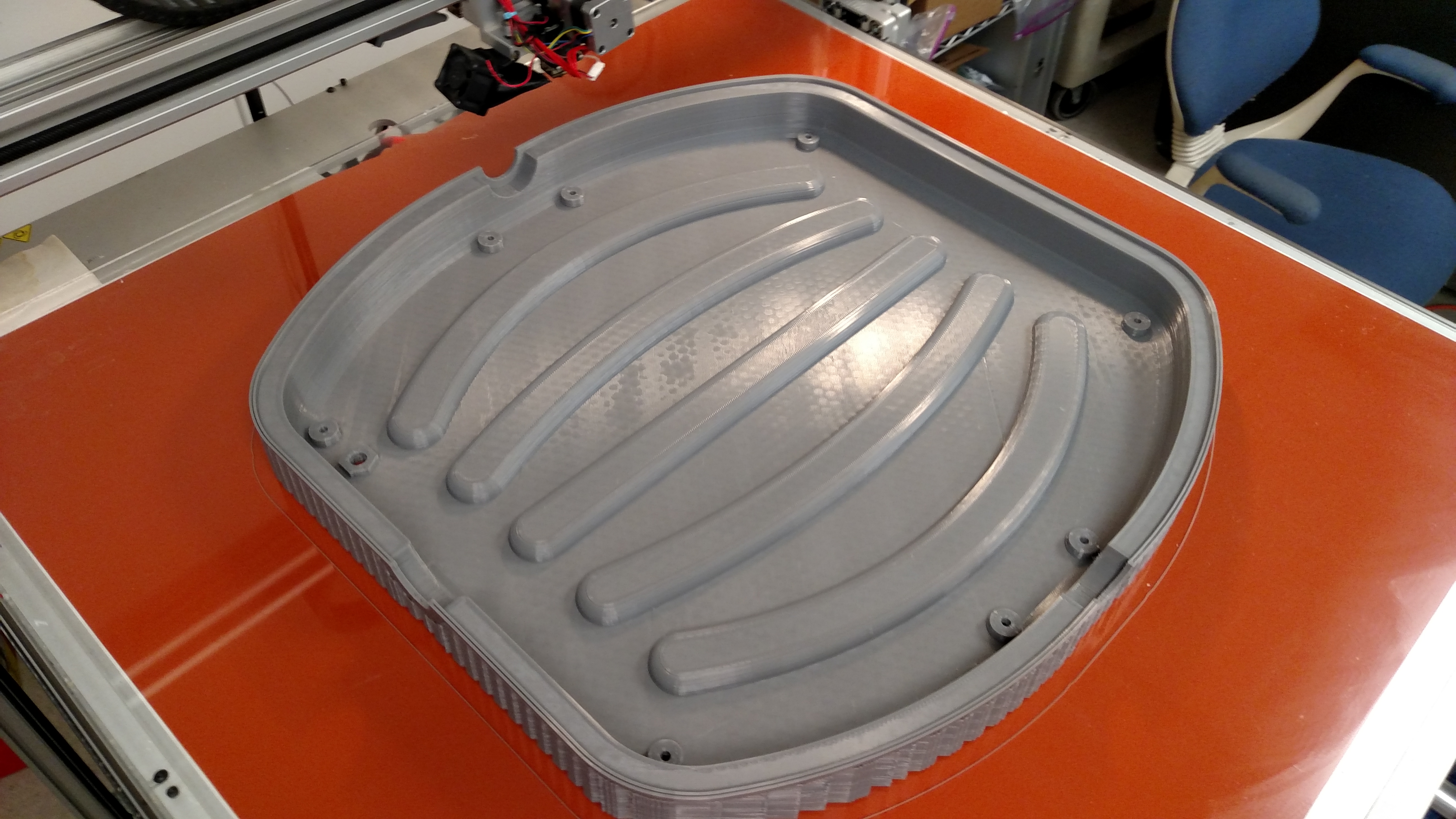

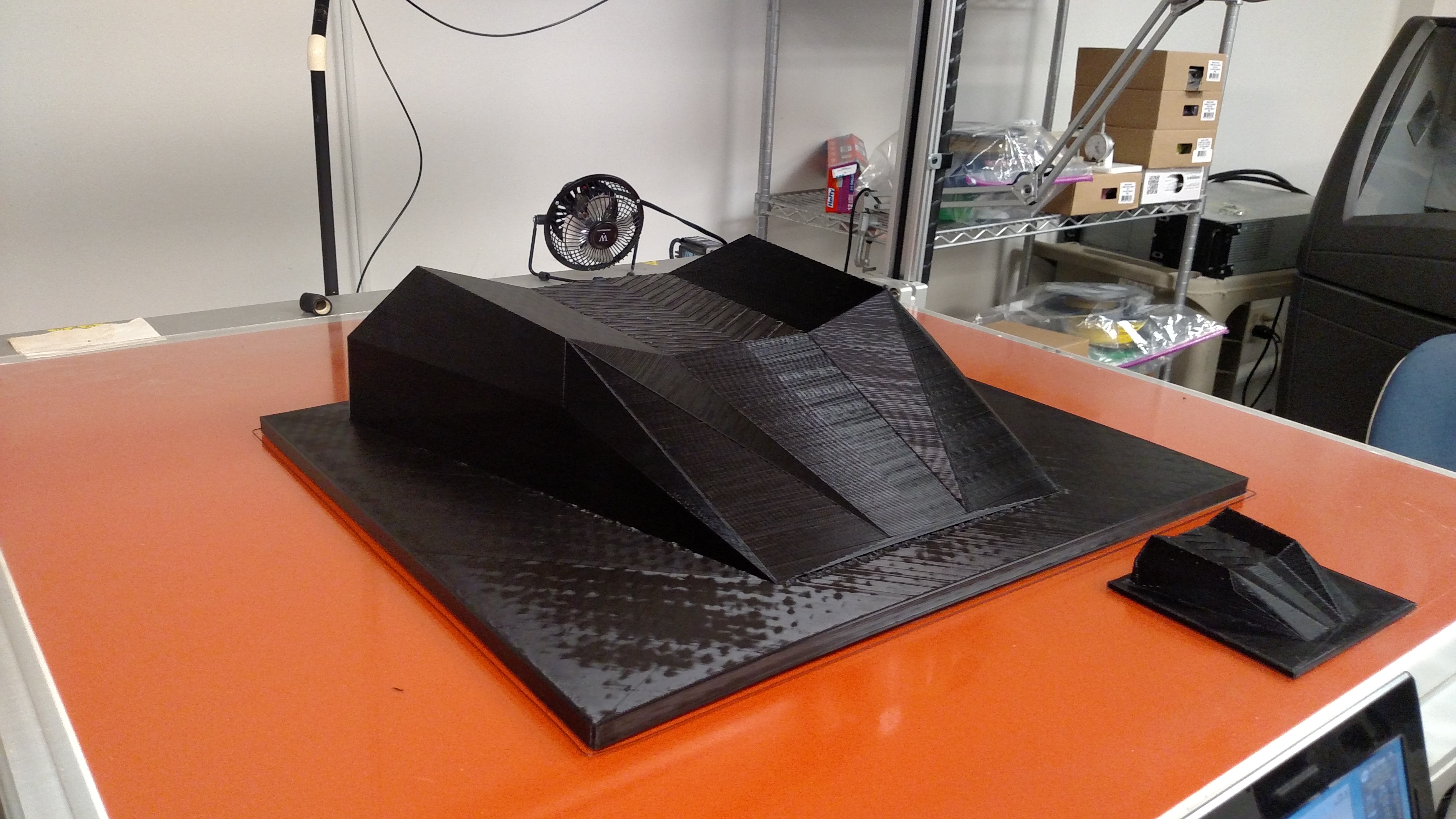

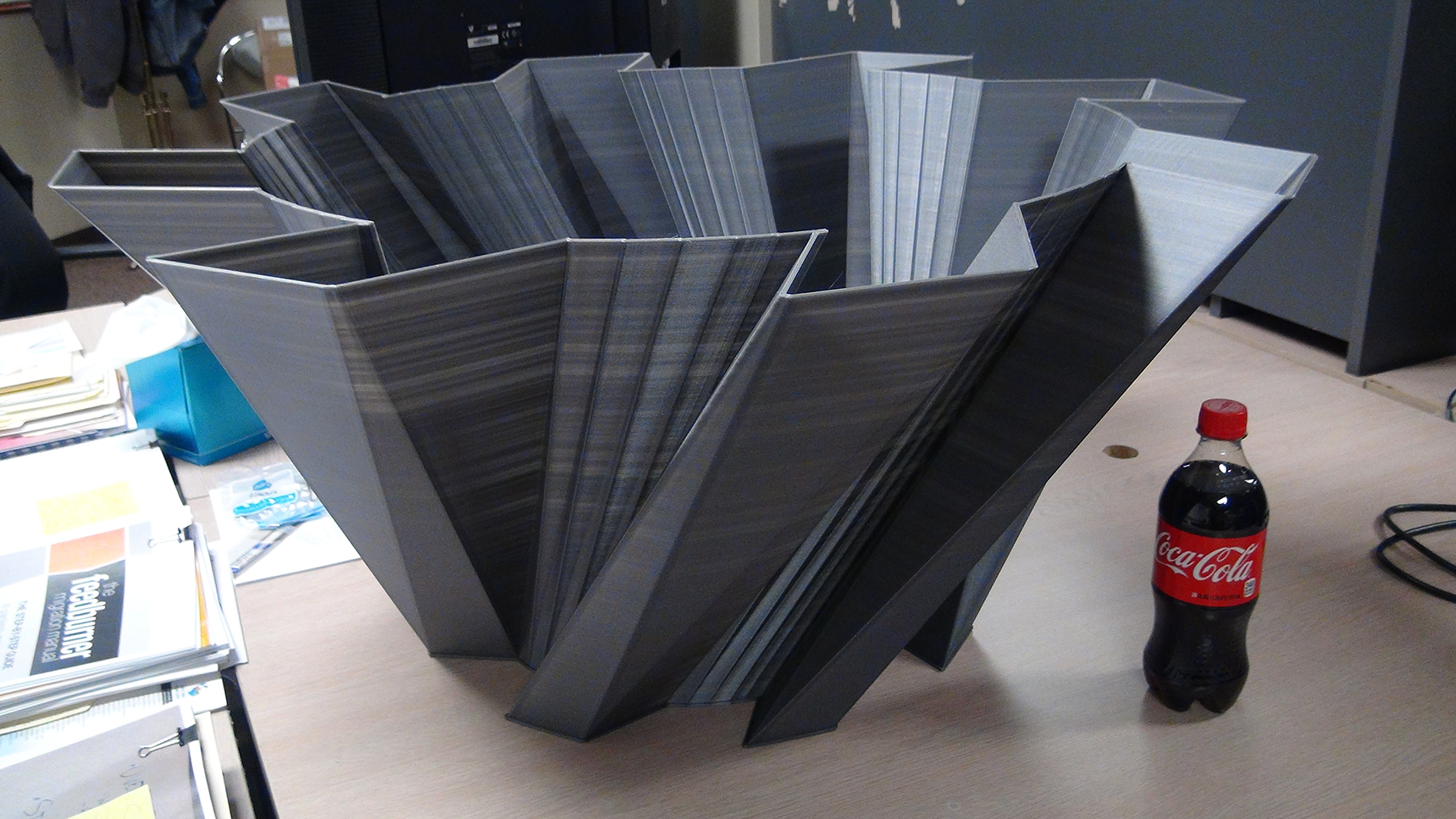

The new x1000 3D Printer was developed for printing large size objects or multi-object prints with industrial quality. Print prototypes, small series, casting cores or architecture and design objects big, fast and precise.

The closed build envelope avoids poor quality prints due to air flow. An automatic door locking mechanism keeps the hatch closed during the printing process for improved safety.

Direct Drive DD3 Extruder with Full Metal Hotend:

New extruder technology, no adjustment necessary, variable contact pressure. High-heatable hotend (up to 290 °C / 554 °F) for industrial filaments. Hotends can be exchanged quick and easily.

Print fast and precise:

A minimum layer height from 0.1 mm allows precise prints. If you need a draft or a less precise object simply use a 0.8 mm nozzle for quick and fast printing.

Feature-rich easy to use printing software:

Easy to use printing software with pre-defined printing profiles and many features.

Filament Management:

Two sensor filament control prevents useless prints due to filament run out

File transfer:

Network compatible via Wifi or Ethernet.

Important safety features for industrial use:

Closed switchboard, emergency shut-down, CO2 fire extinguishing system (optional)

Specifications:

| Extruders | DD3 Dual, 1.75mm |

| Extruder Temp (Max) | 290C / 554F |

| Resolution (max) | 100 microns (0.1mm) |

| Heated Bed | Ceramic Plate |

| Heated Bed Temp (Max) | 110C / 230F |

| Build Volume | 1000 x 800 x 600 mm 39.4" x 32" x 23.6" |

| Nozzles | 0.25, 0.4, 0.6, 0.8mm (std) |

| Speed (Max | 9000 mm/m (50 mm/s) |

| Materials | Open Material Configuration including PETG, PLA, TPU, Carbon20, Dupont Zytel (Nylon), Dupont Hytrel (flexible) |

| Dimensions | 1725 x 1500 x 1320 mm 67.9" x 59.0" x 52" |

| Software | Simplify3D |

| File Transfer | LCD Touch Display, Network based printing via Ethernet or SD Card |

| Options | CO2 fire extinguishing system, 110V to 220V Transformer |

| Voltage | 3 phase 400V (3L+N+PE) or 220V single phase |

| Power | 2500W max |

| Weight | 881.85 lbs. |

In addition to the standard Nylon (PA12) and Flexbile (TPE) materials, the Sintratec Kit is an open-material platform. You can manipulate surface temp, chamber temp and print speed to work with materials of your choice. It is the only desktop SLS 3D printer on the market which has this capability right out of the box!

| Build Volume (max.) | 110 x 110 x 110 mm 4.33" x 4.33" x 4.33" |

| Build Volume (reco.) | 90 x 90 x 90 mm 3.54" x 3.54" x 3.54" |

| Layer Height (min) | 100 microns |

| Accuracy | +/- 0.5mm |

| Minimum Feature Size | 0.5mm |

| Chamber Temperature (max) | 150C |

| Surface Temperature (max) | 180C |

| Laser | 2.3W, 455nm |

| Materials | Nylon (PA12) or TPE Flexible, 60 micron particles |

| Speed | 1.1cm / hr |

| Height Width Depth | 600 mm 520 mm 380 mm |

| Weight | 28 kg |

| Power Connection | 110V or 230V AC |

| Peak Power Consumption | 1700W |

| State Upon Delivery | Unassembled |

| Assembly Time (1 person) | Approximately 4 days |

| Software | Sintratec Central (included) |